Awesome Info About How To Build A Home Foundry

To give a overview of this project, we.

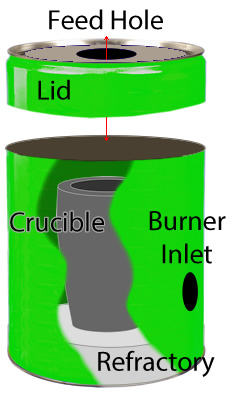

How to build a home foundry. Then cut off the top of it and the middle part. Full hardening to the bottom could take several days, or will. Here you will find what it takes to build a working home foundry.

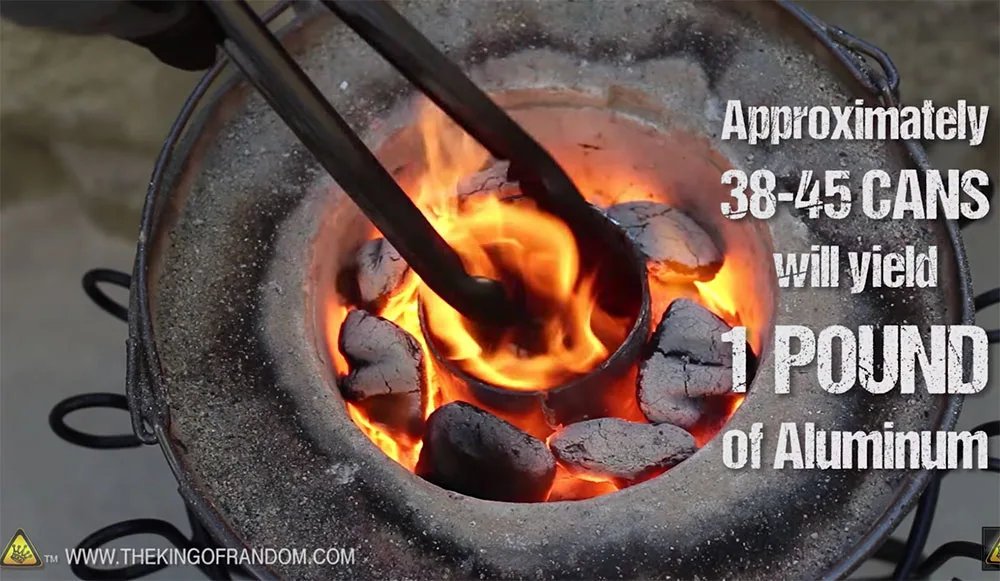

Find a stainless steel pipe or other metal pipe with a high melting temperature place one end of the pipe inside the can with the slits bending down the slits to make a funnel for the air to flow. How to make a simple backyard foundry for less than $20, for melting pop cans, and casting aluminum.[ ] clay graphite crucible: All you have to do is simply cover hardwood ricks with soil and enable them to smoulder for a few weeks from within.

Having a home foundry is on my short list now! How to make a foundry to make a foundry, use an aluminum gallon to ensure the durability of the item. As you push the bucket into the center, the mixture rises upward, but it won’t spill out.

You can easily create your own charcoal to power your own home. And to forge iron & steel.this design allows f. January 4, 2012 at 6:33 pm.

Part 1 of how i made my large mini home foundry forge to melt aluminum, copper, brass, lead, silver, & gold. Turn on the air supply and put the. You can melt any metal you want, as long as.

Fill the bucket with water, to give it a bit of weight, but anything like sand or rocks will work as well. Cut off the top of the gallon and the middle part. A steel cutting chop saw would have made the process much easier.

![Metal Casting 101: Learn To Cast Metal [Types & Processes]](https://www.thecrucible.org/wp-content/uploads/2021/07/Iron-pour_0106-scaled-e1626101365225.jpeg)